Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Influence of Ground Granulated Blast Furnace Slag and Polypropylene Fibers on Engineering Properties of Clay Soil

Authors: Vishav Bansal, Prof. Vinod Kumar Sonthwal

DOI Link: https://doi.org/10.22214/ijraset.2024.63460

Certificate: View Certificate

Abstract

It has become an utmost important to make soil fit to bear the heavy load coming from modern infrastructures and roads and highways, All the pre available soils, sometimes, are not fit to withstand heavy loads as they have weak strength due to more cohesion/ swelling properties or very densely packed particles. Therefore, the exploration of soil properties before and after its stabilization is needed. In current experimental program, raw soil was collected and its stabilization was carried out with the help of Ground Granulated Blast Furnace Slag and Polypropylene fibers. Various strength and other engineering parameters were determined in laboratory but only physical properties of Ground Granulated Blast Furnace Slag and Polypropylene fibers were explored during this study. Therefore, from the various results obtained from different laboratory tests, it was concluded that the optimum percentage of Ground Granulated Blast Furnace Slag and Polypropylene fibers are 40% and 0.50% respectively as at this proportions best results were attained. So, it is highly recommended that 40% Ground Granulated Blast Furnace Slag and 0.50% Polypropylene fibers of waste materials by dry weight of soil should be utilized for enhancing the different properties of raw soil.

Introduction

I. INTRODUCTION

Stabilization of Soil refers to the modification of properties by chemical or mechanical means to create a superior soil material with certain technical characteristics. Soils are often stabilized to enhance their strength and longevity. The objective is to develop a soil material that can withstand the intended usage and remain functional for the planned lifespan of the project. The characteristics of soil exhibit significant variation across various locations and even within a single location; the effectiveness of stabilized soil relies on testing of soil. Different techniques are used to stabilize soil, and it is necessary to confirm the effectiveness of the procedure in the laboratory by using the material.

GGBS is obtained from the quick quenching of hot iron slag, an outcome of the steel and iron manufacturing process, using steam or water. As a consequence of this procedure, a vitreous and granular material is formed, which is further dehydrated and finely pulverized into a powder. The cementitious quality of this substance serves as a binding agent for the soil. Typically, having an adequate amount of CaO leads to increased slag basicity and compressive strength. This waste material is readily accessible and economically viable.

Polypropylene is a fully synthetic fiber derived from 85% propylene, which serves as the monomer for the production of polypropylene. This material is ultimately derived from petroleum. Melt spinning is used to convert polypropylene chips into polypropylene fibers. It is a conventional technique. PP fibers consist of both crystalline and non-crystalline areas in their structure. The fibers are offered in various dimensions, spanning from submillimeter to centimeter diameters.

Needs and advantages of soil stabilization:

- Improves soil strength, leading to increased bearing capacity.

- Increasing soil carrying capacity is a cost-effective and energy-efficient alternative to deep or raft foundation.

- It improves soil stability on slopes and in other areas.

- Soil stabilization may minimize erosion and dust generation, particularly in dry and arid climates.

- Stabilization prevents moisture from entering the soil and maintains its strength.

- It reduces soil volume change caused by temperature or moisture changes.

II. RESEARCH METHODLOGY

This portion discusses the methodology of current experimental work i.e. stabilizing weak soil by using Ground Granulated Blast Furnace Slag (varying 10%,20%,30%,40% and 50%) and polypropylene fibre (varying 0.25%,0.5%, 0.75% and 1% of length 12mm) as shown in table 1.. All the laboratory tests have been mentioned with which the effect of polypropylene fibre and Ground Granulated Blast Furnace Slag was assessed. The research methodology is mentioned as under:

- Raw soil sample was obtained from the vicinity area.

- Determination of Liquid limit, plastic limit and plasticity index was done to determine the type of soil.

- To evaluate optimum percentage of GGBS in soil in different percentage (0%, 10%, 20%, 30%, 40%)

- To study change in properties like Optimum moisture, Maximum dry density and CBR with optimized GGBS at different percentage (0%, 0.25%, 0.5%, 0.75%, 1.0%) and length 12mm of polypropylene fiber

- The effect on Unconfined Compressive Strength (UCS) of soil was also determined.

Table 1. Different Soil Mixes.

|

Soil Mix |

Ground Granulated blast furnace slag(%) |

Polypropylene fiber(%) |

|

Parent soil |

0 |

0 |

|

Soil Mix 1 |

10 |

0 |

|

Soil Mix 2 |

20 |

0 |

|

Soil Mix 3 |

30 |

0 |

|

Soil Mix 4 |

40 |

0 |

|

Soil Mix 5 |

50 |

0 |

|

Soil Mix 6 |

40 |

0.25 |

|

Soil Mix 7 |

40 |

0.50 |

|

Soil Mix 8 |

40 |

0.75 |

|

Soil Mix 9 |

40 |

1 |

Following are the laboratory Tests that were conducted during the study:

a. Plastic limit

b. Liquid Limit

c. Plasticity index

d. Specific Gravity

e. Compaction Proctor Test

f. California Bearing Ratio (CBR)

g. Unconfined Compressive Strength (UCS)

III. RESULTS

The collected raw soil was tested for its atterberg’s limit and other soil index properties to assess the classification of soil as per Indian Standard Soil Classification System. The test results are shown in table: 2.

Table: 2. Soil Properties and Classification.

|

S. No. |

Test Name |

Obtained values |

|

1 |

Liquid Limit (wL) |

37.2 % |

|

2 |

Plastic Limit (wp) |

23.39 % |

|

3 |

Plasticity Index(PI) |

13.81 |

|

4 |

Classification of Soil as per IS |

CI |

|

5 |

Percentage Finer |

51.2 % |

|

6 |

Specific Gravity |

2.641 |

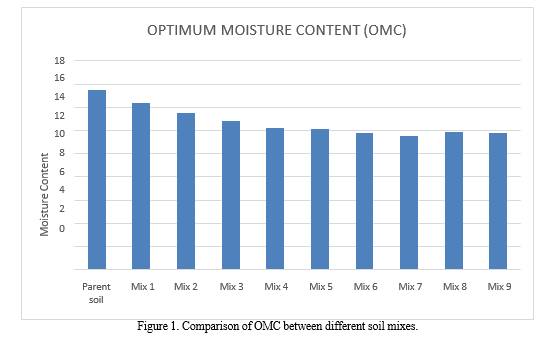

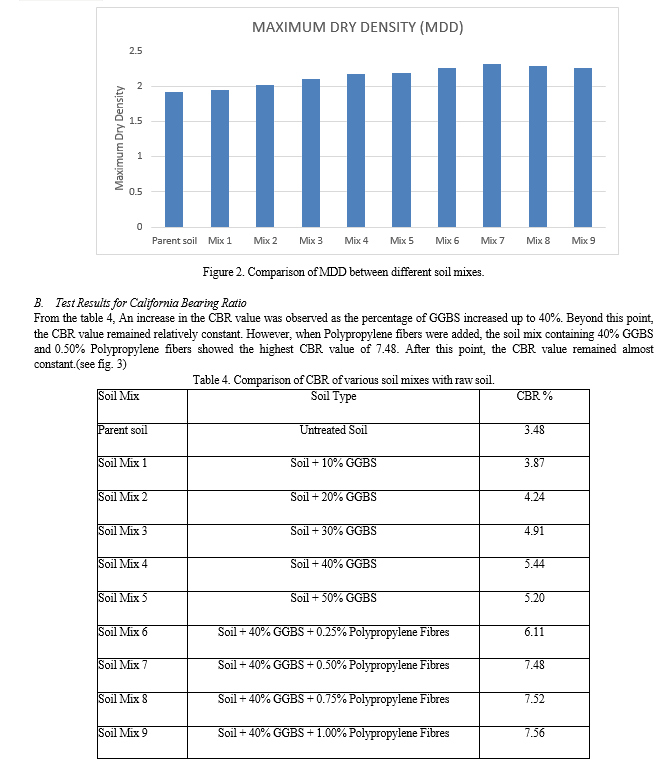

A. Test Results for OMC & MDD

From the table 3, it was found that maximum dry density increases as the percentage of GGBS increases from 10% to 40% and after 40% it almost becomes constant. Therefore, this proportion of GGBS was fixed for further investigation and to analyse the combine effect of GGBS and Polypropylene fibres on soil. It was also seen that maximum dry density increases with 40% GGBS as optimum and the Percentage of Polypropylene fibres increased from 0.25% to 0.50% and then after further increase in percentage of polypropylene, dry density decreases.

(see fig. 1 & 2)

Table 3. Comparison of OMC and MDD of various soil mixes with raw soil.

|

Soil Mix |

Soil Type |

MDD (γd)g/cc |

OMC, (w)% |

|

Parent soil |

Untreated Soil |

1.91 |

15.5 |

|

Soil Mix 1 |

Soil + 10% GGBS |

1.95 |

14.4 |

|

Soil Mix 2 |

Soil + 20% GGBS |

2.01 |

13.5 |

|

Soil Mix 3 |

Soil + 30% GGBS |

2.10 |

12.8 |

|

Soil Mix 4 |

Soil + 40% GGBS |

2.17 |

12.2 |

|

Soil Mix 5 |

Soil + 50% GGBS |

2.18 |

12.1 |

|

Soil Mix 6 |

Soil + 40% GGBS +0.25% Polypropylene Fibres |

2.25 |

11.8 |

|

Soil Mix 7 |

Soil + 40% GGBS + 0.50% Polypropylene Fibres |

2.31 |

11.5 |

|

Soil Mix 8 |

Soil + 40% GGBS + 0.75% Polypropylene Fibres |

2.29 |

11.9 |

|

Soil Mix 9 |

Soil + 40% GGBS + 1.00% Polypropylene Fibres |

2.25 |

11.8 |

Conclusion

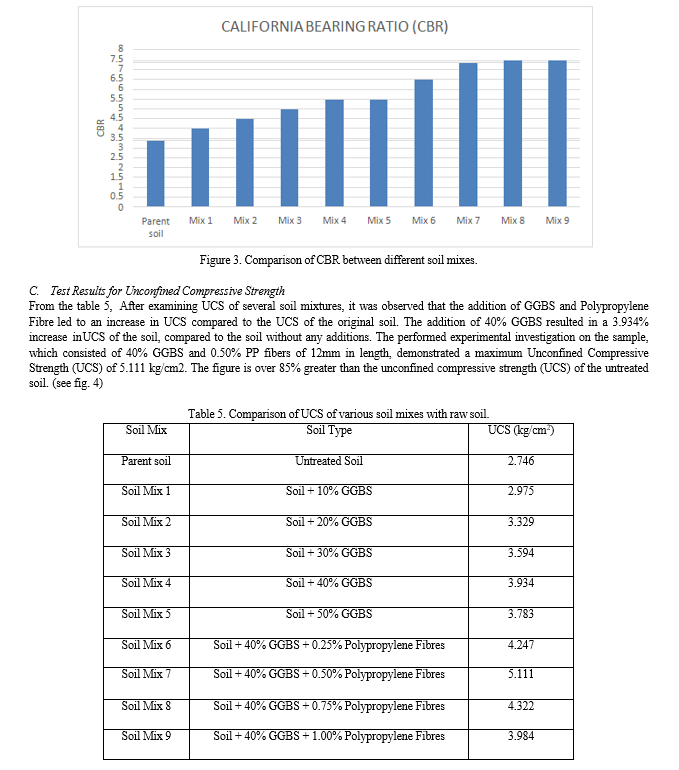

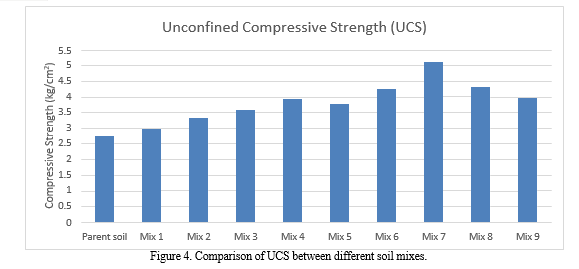

After conducting various laboratory tests on various samples of soil, the present study has arrived to the following conclusions: 1) The values of OMC & MDD obtained for the raw soil from standard proctor test were 15.5% and 1.91 g/cc respectively. 2) From the results of soil having GGBS, it was found that maximum dry density increases as the percentage of GGBS increases from 10% to 40% and after 40% it almost becomes constant. Therefore, this proportion of GGBS was fixed for further investigation and to analyse the combine effect of GGBS and Polypropylene fibres on soil. It was also seen that maximum dry density increases with 40% GGBS as optimum and the Percentage of Polypropylene fibres increased from 0.25% to 0.50% and then after further increase in percentage of polypropylene, dry density decreases. 3) In comparison to raw soil, the soil with 40% GGBS gave the maximum CBR value from all the soil samples containing GGBS i.e. 5.44%, almost 55% increase in the value. Therefore, this proportion of GGBS was fixed for further investigation and to analyse the combine effect of GGBS and Polypropylene fibres on soil. 4) The soil containing fixed proportion of GGBS i.e. 40% and varying proportion of Polypropylene fibres has shown enhanced results of CBR test but the Optimum CBR values was attained at 0.50% of Polypropylene fibres i.e. 7.48%. Therefore, the optimized proportion of GGBS and Polypropylene fibres are 40% and 0.50%. 5) The CBR value of this soil is more than twice the CBR value of raw soil whereas, in comparison to soil containing only GGBS (40%), the CBR value of soil (40% GGBS and 0.50% Polypropylene fibres) has an increase of 39%. 6) The study determined that the inclusion of GGBS and Polypropylene Fibre leads to an increase in the UCS of various soil mixes, as compared to the UCS of untreated soil. The unconfined compressive strength (UCS) of the soil increased by roughly 43% when 40% GGBS was added. Specifically, the UCS increased from 2.746 kg/cm2 to 3.934 kg/cm2 when compared to the UCS of the raw soil. 7) The experimental study conducted on the sample containing 40% GGBS and 0.50% Polypropylene fiber with a length of 12mm demonstrated a maximum UCS of 5.111 kg/cm2, which is roughly 86% higher than the UCS of the raw soil. To conclude the present experimental research work in the gist, it is suggested to use the combination of Ground Granulated Blast Furnace Slag and Polypropylene fibre to improve the various engineering properties of soil.

References

[1] S. Ayyappan, K. Hemalatha and M. Sundaram (2010) “Investigation of Engineering Behavior of Soil, Polypropylene Fibers and Fly Ash -Mixtures for Road Construction” International Journal of Environmental Science and Development, Vol. 1, Issue 2, pages 171-175 Laxmikant Yadu R.K. Tripathi (2013) “Stabilization of soft soil with granulated blast furnace slag and fly ash” Procedia Engineering, vol. 51, pages 125-131 [2] Ashish Kumar Pathak, Dr. V. Pandey, Krishna Murari. J.P. Singh (2014), “Soil Stabilization Using Ground Granulated Blast Furnace Slag”, Int. Journal of Engineering Research and Applications, Vol. 4, Issue 5, pages 164-171. [3] Shish Pal, Vinod Kumar Sonthwal, Jasvir S Rattan (2015) “Soil Stabilization Using Polypropylene as Waste Fiber Material’, IJIRSET, Vol-4, Issue 5, pages 121-126 [4] Satyam Tiwari et al. (2016) “Soil Stabilization Using Waste Fiber Materials” International Journal of Innovative Technology and Research Volume No.4, Issue No.3, pages 2927 – 2930. [5] Sharma, A.K., Sivapullaiah, P.V., (2016) “Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer” ELSEVIER, Volume 56, Issue 2, April 2016, pages 205-212 [6] Sougat Mandal, J.P. Singh (2016) “Stabilization of Soil using Ground Granulated Blast Furnace Slag and Fly Ash” IJIRSET, Vol. 5, Issue 12, pages 21121- 21126 [7] Venkata Rao, Rama Krishna (2017) “Improvement of black cotton soil using GGBS and polypropylene fibers” International Journal of Engineering Research, Vol.5., Issue.2, pages 336-344 [8] N Mahesh Babu, S. Durga Prasad, Dr. DSV Prasad “Effect of Random Inclusion of Plastic Fibers On Strength Behavior of Ground Granulated Blast Furnace Slag Treated Black Cotton Soil” International Journal of Engineering Research and Development, Volume 14, Issue 7, pages 70-75 [9] Pingili Sravanthi, Shaik Khasim Peera (2018) “Compaction behavior of black cotton soil using GGBS and Ordinary Portland Cement” IRJET, Vol-5, Issue:6, pages 1136 – 1139 [10] Sunil Kaswan, Vinod Kumar Sonthwal, Ravinder Singh Panwar, (2018) “Soil Stabilization of Clayey Sand Using Polypropylene Fiber and Fly Ash” IJTIMES, Vol-4, Issue-7, pp-656-659 [11] HeeraLal M, Venkatesh N, Praveen G V (2018) “A Study On Engineering Properties of Black Cotton Soil Mixed with Ground Granulated Blast Furnace Slag and Embedded with Polypropylene Fibres” [12] IJIRMET, Vol. 3, Issue 5, pages 20-25 [13] M. M. Hossain, R.C. Malo & M. H. Safi (2018) “Soil improvement using lime and polypropylene fibres” IJTIMES, vol-5, Issue – 5, pages 226 - 230 [14] S. Durga Prasad, D S V Prasad, G V R Prasada Raju (2019) “Stabilization of Black Cotton Soil using Ground Granulated Blast Furnace Slag and Plastic Fibers” International Journal of Recent Technology and Engineering (IJRTE), Volume-7, Issue-6, pages 633-638 [15] Ravi Kumar Garre, Patlolla Shashidhar Reddy (2019) “Strengthening of Black Cotton Soils by Using Polypropylene as Fiber Reinforcement” IOSR Journal of Engineering, Vol. 9, Issue 1, Pages 27-32 [16] K Bibhu Jyoti Patro, Satyapriya Senapti (2020) “Stabilization of clayey soil by using polypropylene fiber” International Research Journal of Engineering and Technology, Volume: 07, Issue: 08 [17] Hassnen M Jafer, Anmar Dulaimi, W. Atherton (2020) “Incorporating of Two Waste Materials for the Use in Fine Grained Soil Stabilization” Civil Engineering Journal, Vol. 6, Issue 6, pages 1114 - 1123 [18] Chandan Kumar Behera1, Satyapriya Senapati (2021) “Soil Stabilization by Industrial Waste of GGBS and Stone Dust” International Journal of Engineering Research & Technology, Vol. 10, Issue 9, pages 409-415 [19] IS-2720 (Part 16), “Laboratory determination of CBR,” Indian Stand., 1987. [20] IS.2720, “Determination of water content,” 1973. [21] IS-2720(III), “Determination of specific gravity,” Indian Stand., 1980. [22] IS 2720(IV), “Grain Size Analysis,” Indian Stand., 1985

Copyright

Copyright © 2024 Vishav Bansal, Prof. Vinod Kumar Sonthwal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63460

Publish Date : 2024-06-25

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online